|

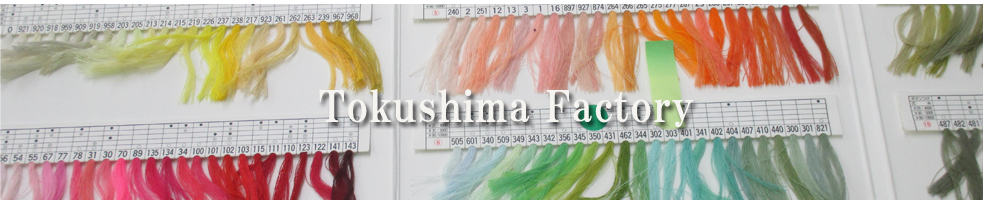

OUR PRODUCT KEEP YARN UP To make until to be a product, we get support from our yarn factory. Our group have yarn factory so the stability of quality our yarn always keep. And if any by chance in emergency condition, it is possible to have an action immediately. |

|

The accumulated know-how and professional technique To imprpve the good efficiency we using dedicated equipment (digitizer, plotter, CAM) sewing system according to ※TSS(Toyota Sewing Sysem) with all manual work. It is also possible to make design by customer request that can not be left to the machine by professional technique. ※TSS (Toyota Sewing System) is a production method where the process until product completion is done by one person. |

|

|

Pursuing to reassurance and safety Mainly we handle children’s clothes so we must pay attention of carefulness. The production site composes it of only a Japanese people and all the workers united and pay close attention to one stitch of one stitch. We always offer the quality of “Made in Japan” every single day. |

Connecting our abilities

Good rawmaterial, good yarn, good fabric. We are connecting our customers with all processes leading up to here. The best cloth with the best design,we want to give a happiness for you. Our inherited technique makes it possible.